|

One of the most important

actions that can help maintain the quality of any good or

service is to collect relevant data consistently over time,

plot it, and examine the plots carefully. All statistical

process control charts plot data (or a statistic calculated

from data) versus time, with control limits designed to

alert the analyst to events beyond normal sampling

variability.

STATGRAPHICS Centurion

provides a very extensive collection of control charts.

These include:

1.

Basic charts for

variable data in which each point

represents the most recent data, including X-Bar and

R charts, X-Bar and S charts, X-Bar and

S-squared charts, Median and Range charts,

and Individuals charts based on X and MR(2).

2.

Basic charts for

attribute data, including P, NP, U, and C

charts.

3.

Time-weighted charts

in which the points plotted are calculated from both

current and historical data, including MA, EWMA, and

CuSum charts.

4.

Multivariate charts,

designed for situations where multiple correlated

measurements are collected.

5.

ARIMA control charts for autocorrelated

data in which the samples collected from one time period

to the next are not independent.

6.

Toolwear charts for monitoring data that

is expected to follow a trend line, not remain constant

at a fixed level.

7.

Acceptance control

charts for high Cpk processes, where the

control limits are placed at a fixed distance from the

specification limits rather than the centerline of the

chart.

8.

CuScore charts, which are designed to

detect specific types of patterns when they occur.

All control charts can be

used for Phase I studies, in which the data determine

the location of the control limits, and Phase II studies,

in which the data are compared against a pre-established

standard. A special procedure is also provided to help

design

a control chart with acceptable power.

Basic Variables Charts

The classical type of

control chart, originally developed back in the 1930's, is

constructed by collecting data periodically and plotting it

versus time. If more than one data value is collected at the

same time, statistics such as the mean, range, median, or

standard deviation are plotted. Control limits are added to

the plot to signal unusually large deviations from the

centerline, and run rules are employed to detect other

unusual patterns.

Basic Attributes Charts

For attribute data, such

as arise from PASS/FAIL testing, the charts used most often

plot either rates or proportions. When the sample sizes

vary, the control limits depend on the size of the samples.

Time-Weighted Charts

When data is collected

one sample at a time and plotted on an individuals chart,

the control limits are usually quite wide, causing the chart

to have poor power in detecting out-of-control situations.

This can be remedied by plotting a weighted average or

cumulative sum of the data, not just the most recent

observation. The average run length of such charts is

usually much less than that of a simple X chart.

Multivariate Control Charts

When more than one

variable are collected, separate control charts are

frequently plotted for each variable. If the variables are

correlated, this can lead to missed out-of-control signals.

For such situations, STATGRAPHICS provides several types of

multivariate control charts: T-Squared charts, Generalized

Variance charts, and Multivariate EWMA

charts. In the case of two variables, the points may be

plotted on a control ellipse.

ARIMA Control Charts

With today's automated

data collection systems, samples are frequently collected at

closely spaced increments of time. Any sort of process

dynamics introduces correlation into successive

measurements, which causes havoc with standard control

charts that assume independence between successive samples.

In such cases, a control chart that captures the dynamics of

the process must be used to properly detect unusual events

when they occur.

The proper chart for such

situations is often an ARIMA control chart, which is

based upon a parametric time series model for process

dynamics. Such charts either plot the residual shocks to the

system at each time period, or they display varying control

limits based upon predicted values one period ahead in time.

Toolwear Charts

Control charts can also

be used to monitor processes in which the mean measurement

is expected to change over time. This commonly occurs when

monitoring the wear on a tool, but also arises in other

situations. The control charts for such cases have a

centerline and control limits that follow the expected

trend.

Acceptance Control Charts

For processes with a high

Cpk, requiring the measurements to remain within 3 sigma of

the centerline may be unnecessarily restrictive. In such

cases, the process may be allowed to drift, as long as it

does not come too close to the specification limits. A

useful type of control chart for this case is the Acceptance

Control Chart, which positions the control

limits based on the specification limits rather than the

process mean.

Cuscore Charts

When monitoring a

real-world process, the types of out-of-control situations

that are likely to occur may be known ahead of time. For

example, a pump that begins to fail may introduce an

oscillation into the measurements at a specific frequency.

In such cases, specialized CuScore Charts may be

constructed to watch for that specific type of failure.

STATGRAPHICS will

construct CuScore charts to detect: spikes, ramps,

bumps of known duration, step changes, exponential

increases, sine waves with known frequency and phase, or any

custom type of pattern that the user wishes to specify.

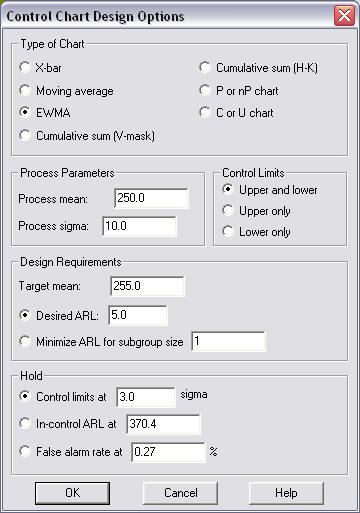

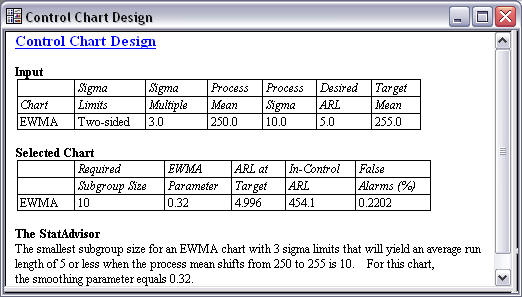

Control Chart Design

For a control chart to be

effective, it must be able to distinguish between situations

in which the process is operating as expected and those in

which it has deviated seriously from its target values.

STATGRAPHICS Centurion provides a procedure for designing

control charts that will detect deviations of a specified

magnitude within an acceptable time. In a typical

application, the user specifies a target mean and the

desired average run length before a deviation of that

magnitude is detected:

The procedure then

determines the number of samples and smoothing parameter

that will achieve the desired performance.

|